Locally Owned Removable Thermal Insulation Shield Manufacturer

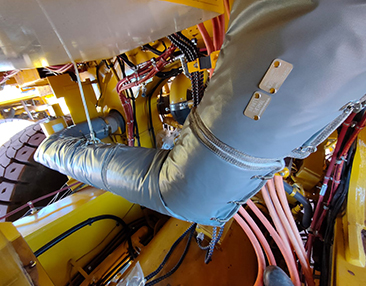

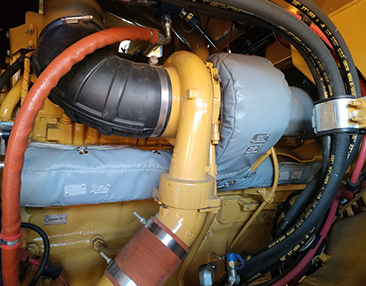

Infinity Group of Companies designs and manufactures advanced removable thermal insulation shields, engineered to protect mining equipment from extreme heat, enhance operator safety, and reduce fire hazards in surface and underground operations.

Removable Insulation Blankets

Infinity Thermal Pty Ltd Removable Insulation Blankets are used to insulate engine parts, exhaust piping and components, industrial process piping and machinery. In particular, applications which use diesel engines, such as power generation, off-highway equipment, trucks, light vehicles, and marine vessels, they often require insulation

blankets to manage the heat that these engines generate. With our extensive library of patterns and designs, we can offer custom removable blanket kits to suit nearly all makes of engines and machines including Caterpillar®, Atlas Copco, M.T.U, Detroit, Komatsu, Liebherr, Hitachi, Cummins and Terex.

What are Removable Insulation Blankets used for?

Infinity Thermal Pty Ltd Removable Insulation Blankets are used effectively to:

- Protecting employee personnel from burn-related injuries therefor reducing OH & S risks

- Increase exhaust system efficiencies and reduce engine compartment temperatures

- Protecting hoses, wiring, and solenoids from excess heat generated from engines and OHS

- Reduce the potential of fires hazards caused by hydraulic oil and diesel leaks igniting on hot surfaces

Many Mine and Construction sites OHS regulations stipulate a mandatory requirement for all machines to meet thermal protection standards of which Infinity Thermal Pty Ltd has helped countless customers to comply with through the provision, back up support and service of their products.

The dense fibrous composition of some of the materials used for heat insulation is also an effective acoustic absorber and these characteristics can be further increased by using multiple layers within the removable blanket products construction. All materials used in our products meet fire rating standards.

How are Removable Insulation Blankets Made?

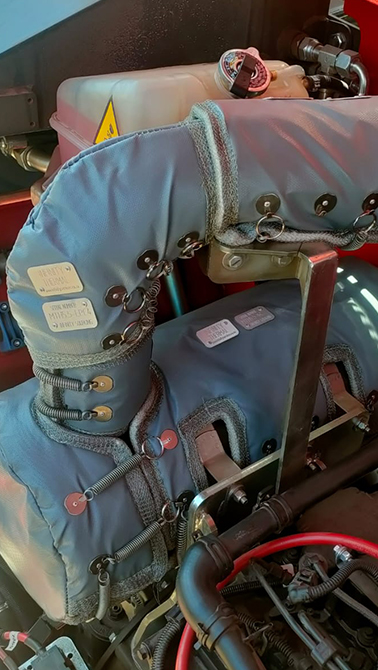

Infinity Thermal Pty Ltd removable insulation blankets are typically constructed in three layers:

- The primary inner layer (hot face) is a layer of Silica cloth, with optional internal encasing of Stainless Steel type knitted Wire Mesh.

- The middle layer is a layer of fibreglass needle mat felt.

- The main outer covering layer (cold face) is a silicon impregnated fibreglass cloth. Other options such as Teflon for greater oil and chemical resistance are available for this layer also. This layer can be optioned with an external layer of Stainless Steel Mesh to give even greater durability and strength. This is generally specified where the blankets are removed more frequently for inspection and servicing.

All edges and seams are stitched using high-temperature Kevlar® thread and fastening systems are high-grade stainless steel anchors, springs and tie wire. The high-temperature silicone infused fabric provides greater product durability and improved resistance to abrasion, flexing, tears and punctures. The heavy-duty fabric is also oil resistant, flame retardant and acid/alkali impervious.

| Layer | Material | Service temp Deg C | Function |

| Inner (Optional) | Knitted Stainless Steel mesh | 650 -980 | Provides extra strength and durability to the inner of the blanket helping to contain insulating media |

| Inner | Stainless Steel Foil. 50Micron Stainless embossed foil | 650 -980 | Offers additional protection on Turbo and Manifold shields where internal leaks are possible |

| Secondary Inner | Vermiculite Coated Silica Cloth | 1000 | High temperature resistant insulting cloth layer for the primary high temperatures |

| Middel | E Glass Needle Felt Fibreglass | 600 | This insulating layer is the material which provides the main reduction in temperatures emanated from the heat source |

| Outer | Silicone Impregnated fiberglass

Teflon Impregnated and coated fibreglass Aluminized Fibreglass |

315

285

260-540 |

Protective outer layer |

Product Range

TURBO SHIELDS

MANIFOLD SHIELDS

SILENCER SHIELDS

EXHAUST SHIELDS

HEAT INSULATING SHEET

STARTER COVER

STAINLESS STEEL RETAINING STRAP

LAVA TYPE INSULATING WRAP

FIRE INSULATING TUBING

HEAT REFLECTIVE COVER

VELCRO REFLECTIVE COVER